Chapter 99

Dress Like a Grownup!'s second year is now behind us! If our first year was the Year of the Average Guy, which introduced you to the world of the well-dressed; our second is the Year of the Miniseries -- for we delved into multi-part topics that added some meat to your knowledge stew. A new reader who finds us through a websearch will be unceremoniously plopped smack in the middle of an ocean of seeming disjointed data: this easy-to-use cross-linkable summary index can be a sort of compass to navigate these waters and find his way around. |

| Giovanni Battista Moroni's Der Schneider (The Cutter,) 1570 |

We'll pick up where 2011's Year at a Glance left off.

We had a full gauntlet of men's formalwear critiques this year. The entertainment industry's offerings ran the gamut, from the decidedly casual Screen Actor's Guild and Billboard Music Awards, to the more formal Golden Globes and Emmys. My coverage of the Oscars was a dual-part affair, also covered at dandyism.net, and we even had time to take a peek at the Kentucky Derby's fashions. 2012 being an election year, we took a look at political fashion as well, from everyday campaign wear, to the black-tie White House Correspondents' Association dinner, and (also our Halloween special!) the white-tie Alfred E. Smith dinner.

We didn't neglect the Average Guy in 2012: there were several essays aimed squarely at the novice just starting out on his sartorial education. The Second Great Secret of Dressing Well was aptly illustrated, (viz., a man tends to dress back to the time when he was most happy,) using real-life examples of celebrities, and the Third Great Secret of Dressing Well (viz., A man cannot break the rules successfully, unless he knows exactly what those rules are,) was observed in the previously-mentioned Kentucky Derby installment. Spring is the ideal time to jump-start changes to your wardrobe, with at least one lightweight coat in your arsenal. We stressed the importance of wardrobe rotation and packing your seasonal items away properly. And we looked at some practical advice on how to match your clothes to the seasons, as well as a close look at the humble sock, and the popular newsboy cap as a proper alternative to a baseball cap. The Average Guy got a taste of some advanced theory with a mathematical look at stylistic balance using the continuum cube.

We completed the Island of Misfit Clothes series that we started in 2011, with re-working a suit jacket that was several sizes too large. After re-shaping the side seams, we narrowed the shoulders, tightened the sleeveheads, set the sleeves in, and put in the lining and finished off the hem. We took a look at fine-tuning the button stance, this time using shanked buttons. And we showed how to make a fine summer-time jacket by way of a quick and simple unlining operation.

There were a great many essays this year with an emphasis on history. We took a look at what Downton Abbey can teach us about dressing well, and used a decoded Mayan apocalypse to introduce a new TT&S Razor Square. The aforementioned political fashion critiques included a comparison to presidential styles of years gone by, as well.

We turned our attention to the history of men's neckwear in a multi-part series; from 1500 to 1800, then from 1800 to 1900. We overviewed men's modern tie choices, then looked at each in turn: long ties, bow ties, ascots, cravats, squares, and scarves.

Our contemplative gaze was directed to the history of tobacco use, to find if an equivalency exists between smokers and being well-dressed. After looking at the timeline from antiquity to 1820, and then from 1820 to the present, we drew our correlations, and concluded that the modern alternative to tobacco would be most useful.

We looked at economies of dressing well, both the economy of time, and the more literal economy of using your purchasing power effectively.

The tale of the Fighting Yank, that was begun last year, was completed this year in two parts: the capture of the criminals, and the raising of the Yank again.

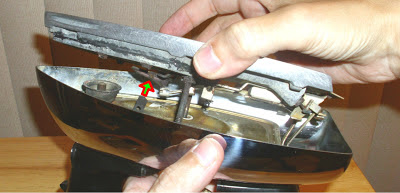

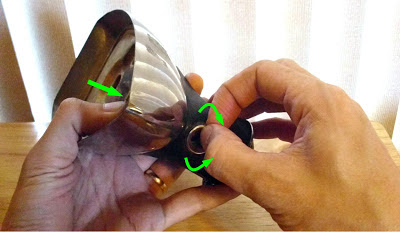

The year ended up with a mechanic's special: a multi-part series that renovated a classic iron -- an essential weapon in the well-dressed man's arsenal. We disassembled, cleaned, repaired, reassembled, and tested an old General Electric to like-new condition.

And of course, we rang out the year with the Razor Square and Bow Tie Men of the Year, our own yearly tradition.

As 2013 rolls on, we will continue to bring you sartorial goodness in one form or another...guaranteed! Stay tuned.

Click here to go to the next essay chronologically.

Click here to go back to the previous essay chronologically.

Click here to go back to the beginning.