(Part 4 of the series, "Iron Man.")

Chapter 96

We've come at last to the end of our journey, and of our Iron Restoration Project. Over the past few weeks we've found a nice vintage iron, taken it apart, discovered what makes it tick, cleaned up the business end, and fixed fifty-odd years of entropy and misuse. This week, we'll turn our attention to the Shiny Bits, and turn back the clock on the exterior as well.

Here are all the exterior components laid out to view: essentially everything save the soleplate, reservoir, and fasteners. All except the cord are subject to a good cleaning: (all we can do with that is subject the plug and boot to an automotive-grade rubber protectant.) Before we turn to the scrubbing, though, we must separate mere dirt and grime from actual physical damage that needs to be repaired.

A good example of reparable damage: a dent on the switchplate. You can see it between the Rayon and Wool settings. This is fairly common on these irons: a sign that at some point it has taken a header off the ironing board and landed on its top-front edge.

The back side of the switchplate reveals the underside of the dent clearly. Fixing it is simple: just dent it backwards. It's an old auto body repair trick: determine exactly how the dent occurred (in this case, a sharp knock along the leading edge, that rolled the deformation out into a semicircular crescent shape,) and apply reverse pressure starting from the outer edge of the roll, and work in.

A wooden chopstick and light hammer work perfectly. Place the end of the stick just where you need it, hold the piece flat against a table, and give it a light rap. Move the stick slightly, and rap again. You'll pick up a rhythm, a tap every half second or so, before long. Work the ever-decreasing crescent inward, ending at the initial knock-point, then turn the switchplate on its end and straighten out the edge. Take it easily and methodically, and the dent will gradually disappear.

Now we're ready to use some more elbow grease. Best to use a shallow tub; you don't want to lose any parts down the sink drain! Put a few inches of hot water and a goodly amount of liquid degreasing detergent, and "borrow" a bristle brush.

Take the pieces one by one and give them a thorough scrubbing until the ages of accumulated crud lift away.

Another handy tip: a wet, wadded-up piece of aluminum foil works wonders on stainless steel, (and chrome, too.)

After all is thoroughly clean and dry, lay all your parts out together. Now is the time of truth and glory -- when everything comes back together!

First, drop in the steam button, remembering to keep the same orientation by which it was removed.

Assemble the three parts of the switchplate and thermostat knob, and slide them home. Hold the steam button up from the underside with one finger at first; then the switchplate will hold the button in place.

Next, screw the handle onto the housing.

Take the reservoir, hold the steam dome in place, and start screwing the plug in by hand. Snug it with your wrench.

Put the spring ring on the fill neck, and slide the stopper rod in place.

Hold the reservoir up into the housing, and press the fill funnel into the hole in the fill neck.

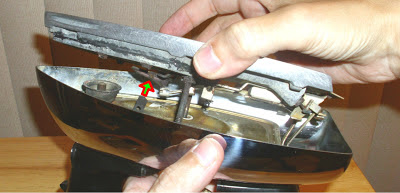

So far, so good -- but now comes the tricky part! The cam turner has to engage between the thermostat knob and the wedge cam, and it has to be done blind: you can't see what the turner's doing when you put the soleplate on. Here's the best way to improve your chances of success. Sight up through the hole in the reservoir until you can see the light shining through the slot in the thermostat lever. That gives you a target to aim for...

...when you drop the cam turner in. Notice that one end is offset and "points" to the knob.

The next thing one would do is cut an asbestos mat the size of the reservoir, cut out all the necessary access holes, and lay it in place. Only one problem with that -- you can't get asbestos any more. It's a wonderful non-conductive insulating material that repels heat. Unfortunately, it also releases tiny airborne fibers that get stuck in your lungs and cause cancer. Thermal-insulating fiberglass mat may be the best alternative...but I don't have any on-hand. Before I go out and buy some, I'm going to assemble it sans insulation and test it that way, to see if it's really needed.

But now back to the cam-turner. Turn the thermostat to the halfway position, so the turner is oriented fore-and-aft.

Then turn the wedge cam 90° so that its slot matches the turner.

Now, carefully lower the soleplate onto the housing. Notice that the cam turner comes in at an angle, so lower the back end of the soleplate first, line up the slot, and lower into place. Check to be sure the turner is engaged by moving the thermostat lever and putting your ear at the baseplate: if you hear the follower sliding along the cam, and the thermostat moves with a little resistance, you got it right. If not, try it again. Be patient; it may take a couple tries.

Turn the iron over, and press firmly on the front of the housing to seat the steam dome into the soleplate. Start the two attaching nuts by hand, and snug them up with your wrench. Then put the trim plate back in place.

Now attach the cord: line up the spade connectors, route the wires as they were originally, and gently snug the screws. Finally, with great ceremony, screw the hatch in place.

We're almost done! All that's left is the final testing. Get out your ironing board and something to iron, a fluffy towel, for instance. Safety first: plug into a GFCI outlet in case of a catastrophic failure...and turn your new iron on its lowest setting. If the GFCI breaker doesn't trip, (or, if you don't have one, if your house fuse doesn't blow!) and your iron gets warm, you know your circuit is sound. Congratulations...you can now plug into any convenient outlet and iron.

But before you actually start ironing, a few more quality-control tests. First, test your thermostat. Leave your iron on a warm setting for a few minutes, and make sure it stays merely warm. Now turn it up halfway, and determine that it heats up a bit and maintains that temperature. If you get runaway temperature, or it doesn't get any warmer, you may have to re-adjust your pivot screw. (And now you know where it is, and how to get to it!)

Smoke! You may get some smoke coming out of the interior of the iron. Your first thought may be to panic, but not so fast. You've been handling the soleplate a lot, and it has been in contact with many foreign substances. It is probably just the oil from your hands burning off, and some flash-curing of the JBWeld we used. Still, keep an eye on it. Turn the thermostat down first, and see if the smoke lessens. If it does, wait for it to stop and then slowly and incrementally increase the thermostat. Fire is bad, obviously, and if the smoke starts really billowing you might have a problem that necessitates taking the iron back apart for a look inside.

Next, test out its steaming ability. Set the iron for steam, put a bit of water in the reservoir, and see if you get that slow, periodic hiss from the water dripping into the soleplate. Hold the iron off of the fabric and see that you get steam out of all the holes, then put it on the towel and make sure you get steam only out of the holes. Back pressure may force steam out of the box lid, or around the steam dome. In either case, the iron has to come apart again, in the one case, to examine the gasket seam and re-apply more JBWeld: you've missed a little, most likely hiding 'way underneath the wedge cam. In the other case, you need to make a little round gasket to fit underneath the steam dome. You may be tempted to live with it, but in the long run, taking it apart again and making sure you have chased down all the steam leaks will be the better path.

And finally, a check on the "conducted heat" factor. Yes, without the asbestos, the handle gets warm. The trim plate under the handle gets very warm. But for daily use, it's certainly tolerable. I wouldn't want to take on a marathon ironing session of every item in my wardrobe, without getting a bit of fiberglass insulation first. And I will, eventually.

I hope this little project has opened your eyes a bit to the benefits of "going vintage." It's true; things WERE made better in years gone by. This elegant, chrome, improbably aerodynamic appliance is sturdier, heavier, and more robust than anything you can buy today, for a fraction of the price. It is, literally, "better than new." And it will still be working, long after a brand-new iron is in a landfill. Now I'm going to gift-wrap this baby, and put it under the Christmas tree.

Click here to go to the next essay chronologically.

Click here to go back to the previous essay chronologically, Part Three of Iron Man.

Click here to go back to Part One of Iron Man.

Click here to go back to the beginning.

Click here to go to the next essay chronologically.

Click here to go back to the previous essay chronologically, Part Three of Iron Man.

Click here to go back to Part One of Iron Man.

Click here to go back to the beginning.

This iron endeavour is more than amazing. I just purchased a vintage GE iron myself, and will pdf this entire article for reference. It is such a relief to see someone take on a cleaning and repair project in the age of disposable appliances! THANK YOU for this.

ReplyDeleteThank you for sharing the information on this beloved iron. I have used mine for over 35 years and before that it was loved as well for almost that long ...

ReplyDeleteNicely done! What method was used to repaint the lettering and details on the switchplate?

ReplyDeleteI particularly appreciate your discussion on building a fashion database and curating a personal style based on individual preferences and long-term goals.

ReplyDeletehttps://promocodehq.com/all-stores

Thank you for sharing this enlightening blog post. It has deepened my understanding of frugalishness in the realm of fashion and creative approach to my personal style.

ReplyDeletehttps://www.frugalishness.com/promotions/all-stores